MAIN FEATURES

- HornCraft™ Stainless Steel Nozzle Design

- BADD™ Hybrid Low-End Technology

- Ten drivers, hybrid construction, six-way crossover:

one 7mm Titanium-Diaphragm DD for infra-sub frequencies

two BA for subwoofer frequencies,

two BA for low frequencies,

two BA (vented) for midrange,

two BA for high frequencies

one Knowles RAU New Generation BA for ultra-high frequencies

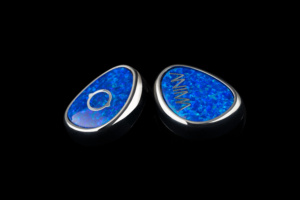

- Hand-finished acrylic shells with Bello Opal™ faceplates (Bello Opal™ with new Stainless Steel Ring Frame)

- Custom Tribrid Cable Featuring Pure Copper, Silver-Plated Copper and Pure Silver

- Handcrafted genuine leather storage case

- MSRP: 3400 EUR

ACCESSORIES ATTACHED:

- Handcrafted genuine leather storage case

- Cotton pouch

- 3.5mm adapter

- 2.5mm adapter

- SpinFit CP145 tips set

- Cleaning tool

ABOUT ANIMA V2

Inspirational Origins: At Lime Ears, our designs are an amalgamation of acoustic exploration. Some inspirations include room acoustics, standalone speakers’ resonance, instrument harmonies and even the acoustics of car exhaust systems (passive radiation). The design factor often traces to jewellery, knife making and watchmaking, creating a harmonious blend of function and aesthetic allure. Unlock the HornCraft™ Nozzle Design and embrace a new era of auditory mastery – where geometry, material, and inspiration harmonize to redefine your sonic journey.

HornCraft™ Stainless Steel Nozzle Design

Horn In Ear – Discover the essence of audio precision with Lime Ears’ groundbreaking HornCraft™ Nozzle Design. Meticulously crafted in-house to perfection, these special horn-shaped nozzles serve as essential conduits, connecting the drivers to your eardrums. With unwavering attention to intricate geometry calculations and material mastery, our goal is to redefine your sonic experience.

1) Geometry That Elevates:

Say hello to the HornCraft™ Stainless Steel Nozzle Design, the pinnacle of geometry refinement. Shaped through VariBore™ technology, its specifically calculated afaik horn curvaturee matches acoustic impedance and suppresses resonances that plague traditional tube designs.

2) Resonance Suppression:

The specific curvature of the horn guides sound waves smoothly, curbing resonant peaks caused by bouncing within straight tubes. This leads to a cleaner frequency response, enhancing sonic clarity.

3) Acoustic Impedance Matching:

Acoustic Impedance matching is crucial for achieving consistent and accurate audio reproduction. Through our meticulously crafted horn bore dimensions, it aids in precise

acoustic impedance matching between drivers and eardrums, resulting in a smoother frequency response and better audio coherence.

4) Material Craftsmanship:

Material’s role is paramount. The harmonious blend of weight, clarity, and transfer is achieved through meticulous craftsmanship. The new highly polished Stainless Steel material, imbued with texture from hand-processing, matches better with internal drivers while interacting with the geometry to enhance high and ultra-high frequencies, directing them straight to your ear.

5) Multi Size Bores – Sonic Symphony:

Look a little closer and you’ll notice precisely selected areas where signals from different groups of drivers are added to the sound mixture. The HornCraft™ design orchestrates an intricate audio symphony, channeling ultra-high frequencies from the longest bore while the lower frequencies get channeled through the narrowest bore. Our Horn nozzles are CNC machined with highest industry precision to achieve ultimate precision transfer of sound energy.

BADD™ Hybrid Low-End Technology

Balanced Armature Dynamic Driver – After long conversations with audiophiles worldwide and dozens of trials utilizing balanced armature and dynamic drivers for low end, we came up with an idea to combine the detail and clarity of Balanced Armature subwoofers with the punch, weight and low-end rumble produced by our 7mm Titanium-Diaphragm Dynamic Driver. With our carefully designed proprietary crossover system, we achieved phase coherence that bridges these two drastically different driver technologies.

HERO™ Super Tweeter

High Efficiency and Resolution Output – It is known that heroes will always come to save the day. Hence, when our electrostatic drivers were not delivering the most optimal treble experiences, we had to bring in a “hero” of our own. Using the HERO™ Super Tweeter, we managed to take the treble performance to new heights. This 2023 new generation Knowles RAU Balanced Armature driver provides an extended treble performance that boasts higher output and resolution without the need for a transformer or high-voltage amplifier. In fact, it is able to cover a range up to 25kHz, double the extension compared to other BA drivers that tend to dip around 12kHz. The greater efficiency is evident in the significantly increased treble output at a much lower volume compared to our previous electrostatic drivers.

The BOSS Faceplate 2023

Bello Opal Stainless Steel – The first extraordinary thing that one would notice is Bello Opal faceplates. This material truly is the king among lab-grown opals. The extremely complex and precise manufacturing process gives it an awesome play of colour, impossible to find in any other material. Lab-grown opals are physically almost identical to natural opals, which is why they’ve gained such a reputation and can be found in jewellery masterpieces around the world. Every piece is unique, with hand-finished acrylic shells and crystals of different shapes and sizes.

As the latest addition to the shell of Anima, we added an outer ring crafted from stainless steel, enhancing its stability and structural integrity. The stainless steel’s gleam harmonizes elegantly with the Bello Opal’s oceanic blue, akin to a precious gem embraced by a ring of brilliance.